Application heads

DGII™

The DGII is designed for flexibility connecting to the adhesive supply hose through either a ball swivel fitting or an axial rotation (rotary) fitting.

BF Mod-Plus Marathon™

ITW Dynatec's BF Series Mod-Plus Marathon™ applicator head is an air-operated, single or multi-nozzle hot melt adhesive applicator assembly with an integrated filter cartridge which prevents particulate matter from obstructing flow through the head. The Marathon's™ screw-on nozzle seat allows fast and easy change of nozzles, and the optional stroke adjustment allows for fine-tuning of adhesive flow from module to module on large lines.

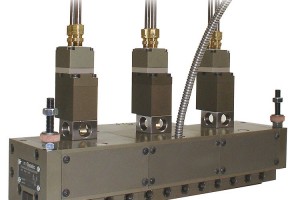

BF Mod-Plus™ Electric Valve

ITW Dynatec's Mod-Plus Electric Applicator Head is an electrically operated, single or multi-nozzle hot melt adhesive applicator assembly with an integrated filter cartridge that prevents particulate matter from obstructing flow through the head. It is used with intermittent adhesive pressure and constant adhesive pressure hot melt adhesive supply units (ASUs).

BF MicroBead™

The BF MicroBead™ applicator is available with single-port or dual-port pivoting modules, providing flexibility for set-up and reduction of the number of applicators required. It’s smaller, more compact design simplifies installation and maintenance while rapid cycle speeds make it an ideal choice for high-speed applications. Its air open/air close design provides accurate and uniform adhesive patterns and bead placement while the built-in filter helps maintain a clean nozzle orifice.

Ultra™ SCS

Ultra™ is a modular hot melt applicator platform, designed for precise adhesive deposition at highest line speeds.

Ultra™ is a modular hot melt applicator platform, designed for precise adhesive deposition at highest line speeds. The advanced Ultra™ SCS nozzle technology delivers precise adhesive deposition with exceptionally-low variability for elasticized legs, leg cuffs and waist bands resulting in increased line speed, reduced adhesive consumption and better consistency in patterns.

Vector™ spray

The Vector™ spray applicator is engineered for precision application onto a variety of substrates with metering accuracy of up to ±0.5% every 25mm in width.

Equity™ Slot Die

The EQUITY™ Continuous Slot Die is a reliable and long-lasting applicator with many money-saving features, making it the best value available in it’s class today.

CrossCoat™

The CrossCoat™ is a non-contact, metered slot applicator that produces a precise flow of adhesive for coating applications that require streak-free results.

LPT/UFD™

Lamiated Plate Technology with Uniform Fiber Deposition - some companies say that they innovate, but only ITW Dynatec has the patents to prove it. (5,902,540 - 5,882,573 - 5,904,298)

APEX™

ITW Dynatec’s APEX High Speed Slot Die Applicator is an air-operated hot melt adhesive applicator assembly with an optional filter manifold. The applicator is used with intermittent pressure and constant pressure hot melt adhesive supply units (ASUs). APEX models are offered in six different module configurations.

DeltaFx™

DeltaFx™ fiberized spray applicators provide exceptional value and flexibility for wide adhesive lamination.

DeltaFx™ fiberized spray applicators provide exceptional value and flexibility for wide adhesive lamination. Using the ITW Dynatec patented Laminate Plate Technology, DeltaFx™ provides an easy-to-use and maintain Non-Contact Application System. An excellent choice for a number of applications where speed, versatility and durability are required that works with all types of hot melt adhesives including PUR Hot Melts.